PRODUCT

METALLURGY 丨 MACHINERY

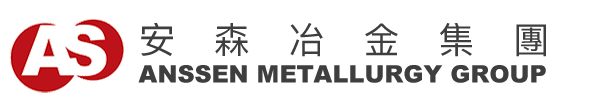

Computer Control Electro-Hydraulic Servo Universal Testing Machine

TEL:+86 411-84390809 丨 FAX:+86 411-84390806

Computer Control Electro-Hydraulic Servo Universal Testing Machine

Computer control Electro-Hydraulic Servo Universal Testing Machine adopts cylinder down-set and six-column mainframe, which is mainly used for metal and non-metal tensile, compression, bending and shear tests. It is applicable to metallurgy, construction, light industry, aviation, aerospace, materials, colleges and universities, scientific research units and other fields. The test operation and data processing meet the requirements tensile test method for metal materials at room.

Standards:

Computer control electro-hydraulic servo universal testing machine can meet standards ASTM, DIN, ISO, GB and so on.

Features:

- 1. The main machine adopts oil cylinder down type, the tensile space is located at the upper part of the machine, compression and bending test space is located between under beam and workbench.

- 2. Strong four-column and two-screw structure design, extremely high stability.

- 3. High pressure internal mesh gear pump, low noise, oil pressure smooth.

- 4. The closed loop servo control system is composed of electric controller, proportional valve, load sensor, displacement sensor, extensometer and computer.

- 5. Mechanical limit protection.

Software Features

1. Accurate and automatic control, real-time display test process, curve and calculate the test force, displacement, deformation and other parameters automatically.

2. Achieve equivalent rate loading, equivalent rate displacement and equivalent rate deformation.

3. Equipped with the computer, software and printer, it can display, record, process and print the test results, and control test procedures according to set program and draw test curves automatically in real time.

4. Have overload protection function.

5. High integration, stable performance and convenient adjustment.

6. Print the testing report according to format of customers’ requirements.

Main Technical Specifications:

|

Model |

WAW-2000Y |

|

Max Load Capacity |

2000kN |

|

Host Machine Structure |

Four-column & Two-lead screw |

|

Range of Testing Force |

2%-100% of max load |

|

Load Accuracy |

±1% |

|

Displacement Measuring Resolution |

0.001mm |

|

Accuracy of Deformation |

±0.5% |

|

Constant Stress, Constant Strain, Constant Displacement Control Range |

2%-100%FS |

|

Max Tensile Space |

800mm |

|

Max Compression Space |

700mm |

|

Effective Test Width |

660mm |

|

Piston Stroke |

250mm |

|

Clamping Diameter of Round Specimen |

Φ15-Φ70mm |

|

Clamping Thickness of Flat Specimen |

0-70mm |

|

Compression Plate Size |

204*204mm |

|

Piston speed: |

100 mm/min |

|

Bending Support Roller Distance |

450mm |

|

Bending Support Roller Width |

140mm |

|

Support Point Diameter |

40mm |

|

Jaw clamping method |

Hydraulic automatic clamping |

|

Control Mode |

Displacement Control, Load Control, Deformation Control |

|

Power Supply |

3phs, 380V, 50Hz |

|

Net Weight |

10000kg |

ADD:No.100 Shengli Road , Xigang district, Dalian China

FAX:+86 411-84390806

CONSULTING & QUOTATIONS

TEL:+86 411-84390809

CONTACT